-

chevron_right

chevron_right

3D-printed Mac replica is a maker masterwork inside an entirely accurate shell

news.movim.eu / ArsTechnica · Tuesday, 19 March - 22:24 · 1 minute

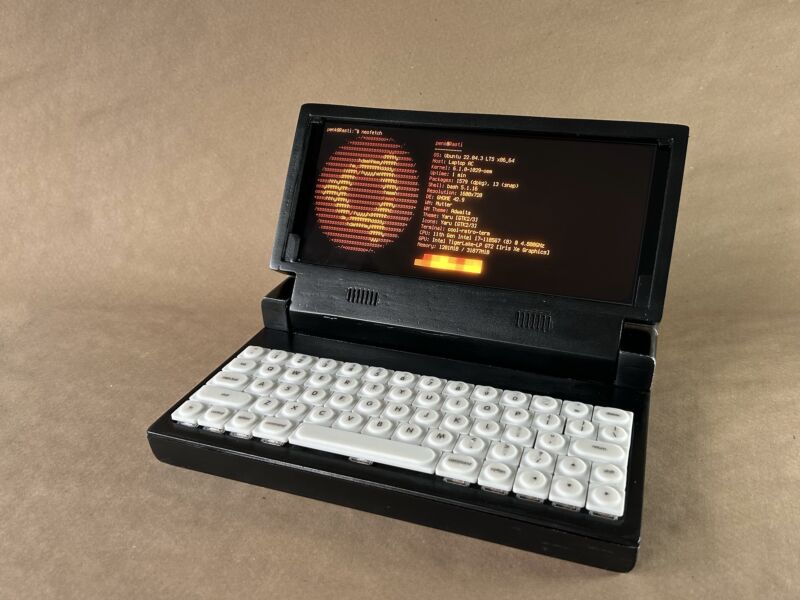

Enlarge (credit: Kevin Noki)

Have you ever worked on a hobby project where modifying and compiling the source code for a Linux-based emulator was possibly the easiest and most straightforward part of the whole thing?

Kevin Noki really, really wanted a functioning Macintosh Plus, complete with a functioning, auto-ejecting disk drive that it could boot from. The German maker already had a Mac Plus (1Mb) from eBay, but it had both a busted power supply and floppy drive. Rather than carve out the busted Plus' one-of-a-kind internals and slap a Raspberry Pi in there like some DIY slacker, Noki went … a different path.

47 minutes and 25 seconds of a tour-de-force of modern maker technology.

Noki 3D-printed his own Macintosh , the "Brewintosh." I would like you to consider what you think that last sentence means and then wipe your expectations clean. I have watched the entire 48-minute journey of Noki's Brewintosh, which is both very soothing on some ASMR -adjacent gut level and also low-key maddening for the way it plays down all the individual accomplishments along the way. Any one of the Brewintosh's pieces would be my entire weekend, and my spouse would not enjoy my mood while I was sunk into it.