-

chevron_right

chevron_right

Here’s how the IRS‘s clean vehicle tax credit will change on April 18

news.movim.eu / ArsTechnica · Friday, 31 March, 2023 - 15:52

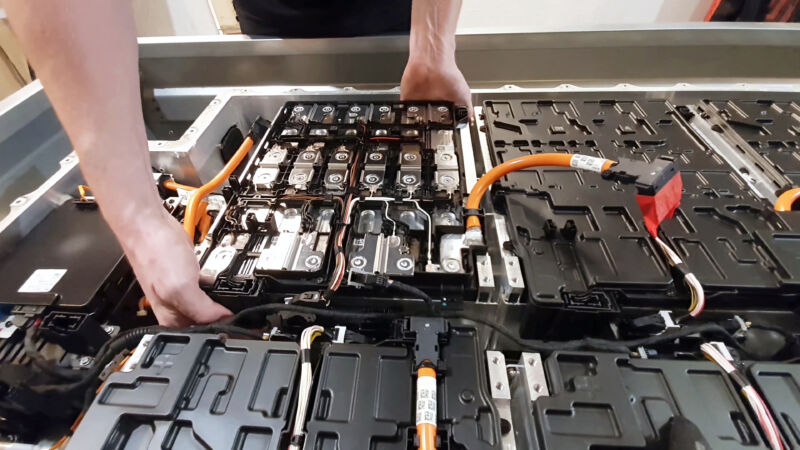

Enlarge / Until the beginning of this year, an EV's tax credit was determined by the storage capacity of its battery pack. Now, the tax credit is linked to local manufacturing of components and locally sourced critical minerals. (credit: Julian Stratenschulte/picture alliance via Getty Images)

It's been a confusing few months for potential electric vehicle customers after the introduction of complicated new rules for the clean vehicle tax credit at the beginning of the year. Now the rules are changing once again.

On Thursday, the Internal Revenue Service published a draft of new guidance for the $7,500 clean vehicle tax credit and said that starting on April 18, it will begin enforcing the domestic sourcing requirement for battery minerals and components. As a result, many new EVs may not qualify for the tax credit.

Tell me the rules again

As we've detailed before , the revised clean vehicle tax credit has quite a few conditions that must be satisfied in order for that vehicle to be eligible.